74-77Camaro.com

My '75 Project

Technical

Home of the Red Headed Stepchildren of the 2nd gen Camaros!

The Great Camaro Shootout

Webmasters note:

To this day, when guys discuss suspension setup on 2nd gen F-bodies, they invariable lapse into the 'stiff spring / small swaybar vs. soft spring / big swaybar' argument, often without understanding where this originated at with regards to our F-bodies. This article was the published basis for that disagreement. I felt this article should be presented for it's historical significance, and although technology has outstripped what they were trying to achieve, a lot of it is still viable on the "modern" street driven 2nd genner.

I hate shootouts! The trouble with them is twofold: First, most people forget the primary objective of the comparison and secondly, they cop-out on the end result. So let's set the record straight about what we had hoped to accomplish when we issued the challenge to both Dick Guldstrand and Herb Adams to pit their suspension theories and parts for F-bodies (Camaros and Firebirds) against each other in a two-day contest to see which is better.

A little background is in order to understand the "real" nature of the challenge. Dick and Herb have been hard racers and arch rivals for a number of years. They have very different ideas on preparing suspension systems for improved street cornering. Basically, Dick has maintained that you should increase the spring rate to improve stability and remove the stock rubber bushings and replace them with polyurethane to eliminate unnecessary deflection that causes a car to be less responsive. Sway bars are used only to fine tune the chassis, not control it.

Herb, on the other hand, feels that the stock rate springs and moderate shock absorber valving is a better approach and that high speed cornering can be controlled with larger sway bars. He claims that a more softly sprung wheel and tire can follow the road surface better, providing greater tire contact and more cornering traction. A more complete explanation of their theories appears elsewhere in this article (see pages 54 and 58).

Who is right? That remains to be seen, but the basis of the controversy is that Dick claims that Herb's car will not work as well as his own setup and Herb maintains that a more severe (riding) suspension like Dick's is unnecessary for the street and even the race track.

The schedule for the two day evaluation was as follows: Tuesday, March 17th - skidpad comparison in Long Beach, CA; Wednesday the 18th - road course comparison at Willow Springs International Raceway, Rosamond, CA. The rules were simple: maximum wheel width - 8 inches, tires - Goodyear Wingfoots with 3/4 tread shaved off (tires provided by Goodyear), street-package suspension kits and, finally, streetable engines. The above rules were rather liberal, but both Dick and Herb complied to the "spirit" of the rules and it made for a good comparison of their suspension systems.

Herb showed up with his well worn '79 Camaro that was decked out with his Stage I & II VSE suspension equipment. The engine was a stocker except for headers (with dual catalytic convertors) and some carb and ignition tuning to the stock pieces.

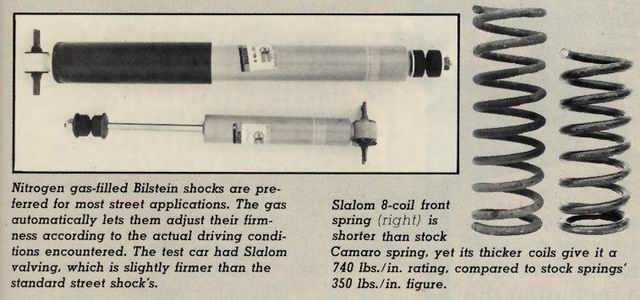

Dick's entry was a '71 Z28 (belonging to a very understanding customer). It was outfitted with Dick's street suspension mods including 30 percent higher rate front springs, polyurethane A-frame and sway bar bushings, Bilstein shocks and Corvette front disc/TA rear disc brakes. The engine was a very nice Traco-blueprinted, low compression 350 that produced about 330 actual horsepower and had one of the broadest powerbands we have ever encountered. The drivelines of both cars were fairly similar with 3.08 positraction rear ends and manual transmissions. Herb relied on a Muncie 4-speed and Disk'c car was already equipped with a Doug Nash 5-speed.

Going in, it seemed like Guldstrand had a slight advantage with the stonger engine, closer ratio transmission and superior brakes. But our individual tests were designed to play down the horsepower differential and in the end they did just that. For instance, the skidpad requires only about a 45-mph cruise so hp would be no advantage; and at Willow Springs we timed the cars through the first six turns (from the end of the front straight to the beginning of the back straight), which limited any straight-away speed advantage to some extent. Two thirds of this section of the course was uphill, so Dick's extra power would give him a slight edge.

Tuesday morning rolled around and we showed up at a large unoccupied parking lot in Long Beach. We had brought three cars, Herb's, Dick's and a stone stock '81 4 speed Z28 Camaro for comparison to the two modified cars. We were all pretty excited and anxious to begin. A skidpad test is nothing more than driving a car around a large circle as it will go without sliding outside the circumference of the circle. The circle painted here was 200 feet in diameter. Some skidpads use larger diameter circles, but 200 feet seems to be the standard. The cornering force (in Gs) is computed by taking the elapsed time that the car takes to complete one lap and plugging it into a mathematical formula:

G force = 122.5 / lap time squared (in seconds)

We timed the laps of both cars with ordinary stopwatches, and with a 200 foot circle you can be very accurate.

The driving technique is very easy. You just straddle the line and slowly accelerate to the maximum speed that you can hold the car on the circle. If you go too fast, the car will usually push the front end out, wide of the circle (understeer), or the back end will try to slide around - a condition normally called oversteer. In either case, slightly lift off of the throttle, get back on line and try to accelerate to the point just before the car starts sliding off.

Herb took me out on the skidpad first in the stock Z28. The object was to show me the driving technique and also to blow the loose sand and gravel off the parking lot. With the tires at stock inflation levels, Herb recorded a 13.06. Then Dick took over and wheeled the stock Z28 to a 13.33. Finally it was my turn and I clicked off a 13.14 while making myself carsick. It was obvious that Herb's driving technique was well honed and Dick and I needed some practice.

Herb was the first "real" competitor out with his black Cheverra. After five laps in both directions, his times averaged 12.06 with a low of 11.93 and a high of 12.29. Then Dick took to the pad with a total of seven laps for both directions (clockwise and counterclockwise) with an average of 12.68 and a low of 12.50 and a high of 12.98. Dick's Camaro was obviously understeering, with the outside front tire smoking heavily. Another factor was present. Dick, being the hard competitor he is, was just trying to drive the car too hard. To bear this out we put Herb in Dick's car and he averaged a 12.41 for five laps. I tried my hand and averaged a 12.45 for three laps.

After spinning many laps around the 200 foot circle and playing with tire pressures, we had enough information to compile the following - Herb's Cheverra, best .86 Gs; average .84 Gs. Dick's Camaro, best .79 Gs (Herb driving), average .76 Gs. Stock '81 Z28 with 32 psi tire pressure recorded a best of .73 Gs and an average of .72 Gs.

Herb's Chevvera had won phase I hands down. Dick and the Guldstrand crew conceded the win. Dick was unhappy with the understeer condition that his Camaro exhibited but quipped "that's what happens when you compete with an untested car." He wasn't making excuses, just stating fact. Both Dick and his crew were also doubtful that the skidpad test would have any bearing on the actual road course the next day. Herb, on the other hand, was feeling relieved and a little more confidant. He felt that there would be many similarities between the skidpad results and the road course from previous experience . . . "If I can only test a car for a short time, I do it on the skidpad. If I can gain a full second there it will mean at least two full seconds off my lap time at the track." Only time would tell.

When the sun rose on Wednesday, I was already on the road for Willow Spring Raceway and our 8:00 a.m. rendezvous. The weather was perfect. Herb and HOT ROD Associate Editors Cam Benty and Marlan Davis were already there and ready to get some track time in. While waiting for Dick to arrive, we took the stock Z28 out for a few laps and Herb showed me where the correct "line" was through the corners. Then we readied the Decateur Eelectronics K-1 radar gun (see sidebar) in the middle of turn 2, a large, slightly banked sweeper that would be the fastest corner we would negotiate. We didn't know for sure which would be the most effective method of evaluating the cars - to use the radar for cornering speeds or the stopwatch for elapsed time through the eight turns.

When Dick showed up we all took turns limbering up with the stock Z28. For a showroom stock car it does an excellent job of getting around the race track. It understeers quite heavily and if we had run the car completely around the course, down the fast straights and the extremely high speed Turn 9 (over 100 mph), both Dick and Herb said that the car would of experienced brake fade and oil starvation in that long Turn 9.

The times for the stocker were as follows: Dick - 63.08, Herb - 64.16 and myself - 64.10. Dick's familiarity with the Willow Springs course and his driving ability were hard to beat. The cornering speeds clocked by the radar gun averaged 75 mph and at that we were pushing it to the limit.

Then both Herb and Dick dook their respective mounts out on the course for the real shootout. It was soon evident that road racing requires a car that does everything well: cornering, braking, shifting and throttle response. If any one of those factors is deficient, it doesn't matter how good the rest of the package is, the performance will suffer. Both cars were well prepared, but each had a minor problem. Dick's car was experiencing downshifting problems and Herb's rear brakes tended to lock up if they were not kept warm. Still, each driver got off more than three runs with no problems. Dick logged a total of 11 timed laps and Herb responded with nine laps. The best for Dick was a 58.40. Herb's best time was a 58.32, both times so close you couldn't call a decisive winner by the handheld stopwatches. (Don't discount the accuracy that can be obtained with a stopwatch, however. With two people timing the same laps, the difference was never more than .1 second and usually closer to .05 second. All that it takes is practice.)

From the elapsed times it would appear that the track contest was a stalemate. To get a truer picture of what was happening, we went to the radar gun in Turn 2. On the average, Herb's Cheverra was consitently 3 mph faster in this turn at 84 mph than Dick's average 81 mph.

So's whose the winner? Let's reflect on what we set out to prove. Do Herb's stock rate springing and factory rubber bushings perform as well as Dick's high rate springs and polyurethane bushings? The answer is a resounding yes. Herb's car pulled more Gs, had higher cornering speeds and identical lap times. Who can argue with that?

But there is more to handling than those criteria Dick points out that a car should be set up to each drivers's style and liking. Dick prefers a stiff, highly responsive car that understeers and can be induced into power oversteer. Herb prefers a more neutral car that can be driven to either understeer or oversteer by driver technique. These are two different schools of thought. They were put to the test and the results are here. You be the judge . . .

By Marlan Davis

Dick Guldstrand has been actively involved in auto racing

since 1947, when he drove a sprint car to victory while still in high

school. Since then, he has driven on nearly every major race course in

the world. Dick's many racing accomplishments include the first ever

Camaro Trans Am series win and victory at the 24 Hours of Daytona driving

a GT class Corvette. Today he continues to assist Chevrolet Engineering

in developing the next generation Corvette, as well as serving as a consultant

to four other major companies. Through all this, he still manages to

find the time to personally work on customers cars in his shop at 11924

W. Jefferson Blvd., Culver City, CA 90230, 213-391-7108.

Dick Guldstrand has been actively involved in auto racing

since 1947, when he drove a sprint car to victory while still in high

school. Since then, he has driven on nearly every major race course in

the world. Dick's many racing accomplishments include the first ever

Camaro Trans Am series win and victory at the 24 Hours of Daytona driving

a GT class Corvette. Today he continues to assist Chevrolet Engineering

in developing the next generation Corvette, as well as serving as a consultant

to four other major companies. Through all this, he still manages to

find the time to personally work on customers cars in his shop at 11924

W. Jefferson Blvd., Culver City, CA 90230, 213-391-7108.

Dick Guldstrand's handling philosophy is simple and direct: "If a car will do what you want it to do, when you want it to, the car is handling well. And that means going around a corner, or stopping, or being under control during all adverse conditions. The minute the car does something other than what you want, it is an ill-handling car. A race car is the most responsive thing you can possibly drive," but unfortunately "a race suspension is so positive you probably couldn't hiccup without changing direction. And I think that requires too much concentration and control for the average person. Consequently, we have to isolate the driver from the absolutes."

On the other hand, a street car has too many rubber parts that eliminate response and most road feel, consequently letting the suspension move around. As a compromise, Guldstrand has developed polyurethane and nylon parts "that will allow you to do probably 75 percent of what the metal will do." And unlike race only parts, such as metal bushings and heim-jointed strut rods, "which wouldn't last long enough to go from here to New York" and "would probably jar your teeth out," polyurethane and nylon parts will last about as long as the stock rubber pieces without being unduly harsh.

Getting down to specifics, every car - from an Impala to a Z28 - comes out of Detroit with varying amounts of understeer. That's not to fault Detroit, which is only building what 90 percent of customers want - "A cushy, soft, easy riding car that is totally unresponsive. There are very, very few people in the United States who can really drive a car well, or are even interested enough in the vehicle to drive it properly, so you must make the car totally forgiving, or you're going to hurt a lot of people."

The other 10 percent are the market Guldstrand caters to. How he "rights" Detroit's "wrongs" is influenced by his theory on the way a suspension works. According to Dick, the most important handling component is "undoubtedly the tires." Modern high performance rubber represents "the biggest single suspension development that has occurred in the last 20 years." The best of the new breed is Goodyear's Wingfoot, which to Dick feels even "better than a P7 Pirelli. They're better in the wet, they last longer, they're a third of the price." Race tires are to be avoided. "There is very little rubber on a race tire and if you run over any little obstruction or anything, chances are that it'll blow out. A race tire has to run at a temperature of over 150 degrees to work" - a temperature seldom reached in street driving.

The tires must be mounted on the proper size and offset wheel. Suspension and brake clearance dictate the amount of wheel offset required. Ideally, the offset should be kept at 0 or 1/2 inch positive at most. "You don't want to push the tire out from under the wheelwell; it'll destroy wheels bearings and ruin all kinds of suspension functions." The wheel's maximum width and diameter are determined by fender clearance, which on a Camaro allows for a 15x8 wheel. The wheel size in turn determines maximum tire size. With an 8 inch wheel, "the tire that is required shouldn't have more than 8 or 8 1/2 inches of tread pattern on the ground because the wheel must vertically support that tire." Putting too large a tire on too small a wheel can result in the tire coming off the wheel under hard cornering. Additionally, "the wider the tire, the greater the heat buildup required" for the rubber to reach its maximum adhesion potential. Dick usually recommends the P255/R60-15 size for the Camaro.

While it's desirable to keep the rubber warm, ideally air temperature and pressure buildup inside the tire should be kept down. This is accomplished by running relatively high inflation pressures. This gives the tire better compliance, thereby resulting in less temperature and pressure buildup. For most street driving, 30 to 32 psi is the norm, with up to 40 psi being run on street tires used in competition. Front and rear tire pressures can be varied by approximately 2 to 4 pounds as a fine tuning device - more air up front tends to make the front end stick better, additional air in the rear will reduce oversteer.

Of course, the wheel and tire combination must be properly aligned. Dick puts particular stress on achieving the correct caster. "You've got to look at caster as alignment torque. The more caster, the straighter the cars goes and the slower it steers, so what we like is to put enough caster into the front end so that the steering wheel will return and there isn't too much caster to where it'll steer too slowly." Also, "with additional caster, turning the corner overcomes kingpin inclination, which means you keep the tire flatter to the ground." Otherwise, the tire will "turn over on the letters." In general, for GM's F-bodied cars Dick recommends 2 to 2 1/2 degrees positive caster and 0 camber with between 1/8 to 3/16 inch toe-in.

After getting the tread in the proper relationship to the pavement, the next step is to keep "all four wheels firmly planted on the ground." That's where the suspension itself comes into play. Remembering that the biggest problem of US cars is understeer, Dick's solution is to "increase the front spring rate or roll coupling (the amount of energy it takes to make the car lean over)." Roll coupling can be increased one of two ways: with springs or a combination of springs and swaybars. Dick relies on springs. "If you don't want the car to be a go-kart and attach it directly to the frame and to the driver, ou would probably want to put springs on it. That would isolate some of the shock, vibration, and terror out of Mulholland Drive. Considering that the '71 Camaro (used it the shootout) has about 57 percent of its 3552 pound weight on the front nose, the biggest problem of course is going to be on the front end." To compensate, Dick installed a set of his heavy-duty slalom springs up front; the rear leaf springs were adequate and were left unchanged.

"The springs generally hold the car up, but you'll find out that it'll start bouncing up and down to where the wheels will come off the ground and you will ultimately die. So then you have to dampen that with shock absorbers, which don't hold up the car, they damp oscillations, the bouncing up and down of the vehicle."

Where then do sway bars come in? Says Dick, "They're not really a major part of the suspension. Remember we spent all this money to individually suspend all four wheels. Why on earth do you want ot tie them all back together again and make it ride and handle like a Model A front end? The sway bar is basically a tuning device to alter or improve handling characteristics such as eliminating unwanted under or over steer." They should be used to fine-tune the chassis after the spring rates are determined by what's necessary to support the car and prevent nosedive under hard braking.

Why then the over-emphasis some people put on sway bars? "Sway bars are a real cheap, simple, straightforward fix. It takes 10 minutes to bolt a sway bar on. It takes a lot of time to design a spring and stick it on a car." Adding a sway bar is like taking a cold capsule - it relieves the symptoms, but doesn't really "cure" the patient. With a sway bar, "when you roll a car into a corner, you will be applying the weight of that particular car to the hard side of the car, and you'll be trying physically to pull the other wheel off the ground." All the load will be transferred to just two tires, which possibly could exceed their load limit and cause them to fail.

There are several additional chassis mods recommended by Dick. One is lowering the car, which improves vehicle stability and cornering ability by lowering both the center of gravity and the vehicle's rollover moment. Of course, there are limits to how low a street car can be taken down and still remain suitable to drive on the public highways; the test car was 1.5 inches down in the front and 1 inch in the rear, accomplished by cutting coils from the front springs and using Dick's rear leaf spring lowering kit.

The other mod is replacement of the rubber subframe bushings by either an aluminum or polyurethane bushing to prevent unwarranted front suspension geometry changes. Aluminum bushings are considered unduly harsh for the street and subject to rapid wear. Polyurethane subframe bushings are under development and should be available by this summer. The test car ran with stock rubber subframe bushings.

The rest of the car must keep up with the suspension. For one, you've got to stop. The stock brake pads and shoes can't do the job. "If you've ever tried to stop three times on a freeway from 60 mph, you'd better do a lot of praying, because about that third stop you're going to be in trouble." To cure this brake fade, Dick sells three different pads - the inexpensive Thiocol semi-metallic pad, the more expensive Bendix semi-metallic and the full metallic pad. The latter isn't recommended for the street because of its poor cold stop characteritics. "The first stop in the morning, you've got both feet on the pedal and you're saying your rosary." Once you've got the metallics heated up, they do "stop better than any other" and "will last five times longer than any organic pad." The stock front disc / rear drum brake system will perform satisfactorily with the stock pads in most street applications. For more severe use, the late Trans Am rear discs can be added by either swapping an entire rearend or bolting the brakes onto an earlier rear. For the ultimate in braking, high-performance Corvette calipers can be installed. They offer such an increase in brake area that you can get by with organic linings, as was the case with the test car.

The drivetrain also interacts with the suspension. A posi rear end is highly recommended for cornering consistancy. Manual transmissons are preferred over automatics because "there's much more control with a manual transmission. The automatic transmission and its torque converter takes away some of the responsibility from the driver and it'll do what it wants to when it wants to do it." The test camaro had perhaps the ultimate transmission (at least on paper): the Doug Nash 5 speed.

Once you're generating over .7-.8 G lateral adhesion, the chances are excellent that the engine oil pump is going to cavitate. All motors can benefit from a Mecca Accusump as sold by Guldstrand, Auto World, H-O Racing and others. This "poor mans dry sump" contains a three quart oil reserve under pressure that's instantly supplied to the engine when pressure is lost for any reason. Chevy big blocks are 50 percent more susceptible to cavitation than the small Chevy or Pontiac, and absolutely must use this system. Over 1 G, all engines need a dry sump.

Last, but not least, there's aerodynamics. The rear spoiler may look good, but it doesn't really work until 75 mph. Much more important is the front air dam, which is effective from about 25 mph on up. Not only does the dam transfer additional cooling air to the radiator (and front brakes, if ducts are used), but by keeping air out from under the car it creates a negative pressure area, in effect "gluing" the car to the road surface.

Which is what Dick's cars do: stick like glue - on dry pavement or wet. If you have a GM F-body or Corvette, why not "spring" ahead with one of Dick Guldstrand's slalom setups?

Herb Adams

By Cam Benty

Herb Adams is one of the foremost authorities on suspension design and development. He spent 17 years with the Pontiac Motor Company in a variety of capacities including Special Projects Supervisor. A graduate of General Motors Institute, Adams was responsible for such projects as the '69 and '70 Firebird Trans Am and GTO Judge packages from Pontiac. Projects since that time include an experimental "Ultimate Trans Am" for Pontiac, which was not only suited for street driving but was also competitive in road racing events. In racing circles, Adams constructed the Milt Minter-driven '72 Firebird which collected a Trans-Am victory at Mid-Ohio in '72, ending a nine year drought from the winners circle. Adams was the creator of the Trans Am category II Silverbird in 1978, which raced for several years before Adams constructed his 1981 Cheverra (Camaro) which saw action at the 24 Hours of Daytona this year. Adams' parts and pieces are available seperately or installed on a Camaro or Firebird through his headquarters at 125 Ocean View Blvd., Pacific Grove, CA 93950, 408/372-2767.

Adams says, "There are three major points which make up a good handling car. First the car should have good cornering power as part of the total package. It should be able to exert good adhesion properties in a corner; however, this is not the sole criterion which makes a good handling car for it must also be able to go straight. Cornering power is necessary for safety.

"Second, the car must feed back to the driver exactly what it plans to do, so that the driver can adjust. High-effort steering gear helps the driver feel the road, as do good brakes and a tuned suspension, which don't lull the driver to sleep with a too soft ride."

"And third is controllability; the ability to maneuver the car through a transition from one side of a turn and out the other. This is where we use the stabilizer bar to straighten out the body deflection and take the car through a turn."

This is the theory behind the Herb Adams line of performance handling gear for the F-body Camaro/Firebird (Adams recently introduced a handling line for the '67-'69 Camaro/Firebird as well). For the "HOT ROD Shootout", Herb usitlzed his test car, a '78 Cheverra (Camaro with Adams package), using his complete Stage I and Stage II kits. Stage I encompasses a front and rear sway bar change, adjustment of the rear leaf spring mount, relocation of the battery into the trunk, a rollbar, lowering of the front end with subframe bushings and cutting the stock front springs, addition of front strut bars, steel 0-offset 15x8-inch wheels and P225/R60-15 shaved wingfoot tires.

The Stage II modifications are for cars which will see slalom competition and were considered necessary for the Willow Springs competition. Stage II includes Koni Adjustable shock absorbers, mettalic brake linings and cooling modifications, an oil cooler and Corbeau seats were replaced by a set of Recaro seats.

Other modifications to the Cheverra used in the shootout included Stahl street headers leading back to 2-inch tubing, twin catalytic onvertors and twin resonators. A Muncie 4-speed transmission and Hurst shifter were used along with 3.08:1 rearend gearing. For race day, the 350 cubic inh engine received and extra quart of oil in the crankcase to avoid loosing oil pressure in hard cornering.

"The single most important factor in handling is the type of tire used and how effectively it is put to use. Basically, it all boils down to how the tire contacts the road, how perpendicular it is and where it is pointed." Said Herb. "On both our race car and streetable Chevvera we use Goodyear Wingfoot tires shaved to prevent tread flexation. On the race car we use the Wingfoot with a 10 inch rim. However, on the Cheverra the 0-offset VSE wheel and the 255 Wingfoot make a perfect match."

In an effort to keep the wheel perpendicular through the corners, Adams suggests a camber setting of one degree negative, and to keep the wheel pointed correctly a one degree positive caster setting. To compensate for tie rod flexation, a 1/16 inch toe0in setting is used. The only difference between the street and race setting is a change to three degrees negative camber for the race car, where higher rollover occurs because of higher speeds. At top speed it is crucial to stand the tire up by increasing negative camber.

Basically, Adams relies on the theory of soft springs and stiff sway bars to accomplish his three points to a good handling car. The soft springs are able to follow the contours of the road more easily than stiff springs, which can cause the tires to become airborne on an irregular surface, jumping from one bump to the next. Tire contact with the ground is essential to controlling the car.

Helping to work against body lean and deflection is the sway bar which uses lever action against the control arms and rear axle housing. The diameter of the sway bar and the length of the bar between the control arm or housing mount to the frame determines the effectiveness of the bar. As the control arm or rear housing deflects, the sway bar is forced to flex. As it works to right itself, it forces the frame and body of the car back to its neutral position. "Different diameter bars (or mounting positions) affect the car differently, causing understeer or oversteer tendencies. Ideally, a car which is neutral at best, allowing the driver to induce understeer or oversteer by driving technique."

A unique modification to sway bar mounting in the Adams Cheverra is the use of heim joints instead of the standard threaded rod and bushings used in stock sway bar appliactions. This modification alone is responsible for more effective use of sway bar leverage. On the Cheverra the front swaybar is 1 5/16 inch as opposed to a 1 1/8 inch bar on the stock car. Herb said, "I've never seen too large a front sway bar. The reason we only have a sway bar 1 5/16 inches in diameter is because my iron bender wouldn't bend anything larger." In the rear, a 1 inch bar is used instead of the stock 5/8 inch bar. The frame mounts for the front bar are the stock rubber units, while in the rear the body mounts are rubber and the spring mounts are polyurethane to induce a slight amount of understeer.

Another device used by Adams to control deflection of the body and suspension components is a front strut which mounts between the upper control arms and the firewall. This strut dampens deflection of the wheel, minimizing the change in the camber, caster and toe-in, and keeps the tires in line.

"The weakest point to the F-body configuration is the structure of the car; it twists, bends and ultimately cracks in places, making it difficult to achieve complete control. Overall, the design of the suspension and overall layout of the car is excellent, but due to its mass-produced status, there were a number of compromises made which can be corrected."

"A major point of flexation is between the subframe and the body of the car. Anyone who has tried to open the door when the car is jacked up knows that it can't be done because the whole car sags and binds the door. At this subframe joint, we remove the rubber bushings and install a pair of 1/2 inch aluminum spacers covered by a rubber cushion to insulate the joint, sound-wise. This effectively lowers the car a full 1/2 inch."

Another lowering trick is to remove the front coil springs and cut off a full 1/2 coil. Another 1/2 coil is heated and bent flat to keep the spring from moving in the spring tower. "With the stock springs we have had no problems with bottoming out, which would necessitate the installation of stiffer springs. The stock Camaro/Firebird heavy duty spring has a .675 wire diameter and is rated at 350 pounds per inch.

"We further improved the steady state cornering by moving the front eye of the rear leaf spring up 3/4 inch, which reduces roll understeer. This change also lowers the rear of the car, but more importantly increases anti-squat in the rear suspension (the resistance to having the rear of the car push down under acceleration). In other words, the modification forces the tires down on the road harder, increasing traction and cornering power."

Adams keeps true to form in his belief that the tire must remain in contact with the road by using Koni adjustable shocks set on the softest setting in the rear and the medium setting for the front. "Most of the time we suggest the medium setting on both the front and the rear. However, because of the long highway driving necessary to come to the contest, the soft setting netted a much more comfortable ride."

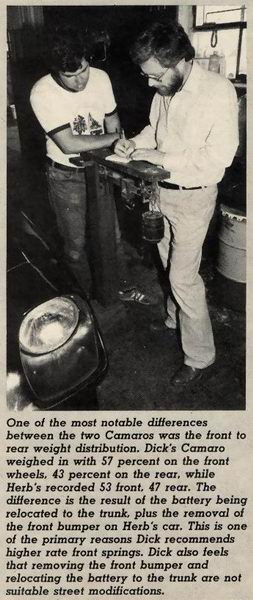

Weight distribution is as integral to good handling as proper tires and wheels. The test vehicle registered a remarkable 53/47 front to rear weight distribution for the total 3637 pound package; perfect for the F-body configuration. This ratio was achieved through two major modifications. The first was the relocation of the battery to the trunk.

"This modification alone is equivalent to moving the engine back 10 inches in the frame," said Adams. "The net result of a change is a matter not only of how much weight is moved, but also how far it is moved. Moving the 50 pound battery from the extreme front of the car to the extreme rear has major weight distribution results."

The other modification ws to remove the impact bumper system from the front of the '78 Camaro. A total of 100 pounds was removed and replaced by a fiberglass front end complete with front air dam.

Airflow across a car greatly affects the handling characteristics of the machine. The advantage of the air dam is that it keeps air from under the car and forces the hood down, thus improving front tire traction and increasing radiator cooling by forcing air through the nose. The rear "whale tail" is mainly for cosmetics in this application, but it does apply some down force to the rear end, increasing rear tire traction.

"Frontal air dams are very beneficial, despite public opinion that they are simply cosmetic," said Adams. "Their effectiveness is a function of the speed of the vehicle, squared. In other words, if you increase your speed by double, the effect of the spoiler quadruples."

Also benefitting from the front air dam are the brakes. Ducts in the dam take air from behind the grill and force it into the front brake caplipers. Each front brake utilizes mettalic brake pads and backing plates which have a fitting for the attachment of the cooling ducts. In the rear, metallic linings are also used, with holes cut in both the brake drum and backing plate to keep air circulating through the system. Holes in the VSE wheels also help keep air moving through the brake system. It should be noted that the metallic linings were used because of the Willow Springs testing, and are not recommended for street driving where semi-metallic linings should be more than adequate.

As noted earlier, one extra quart of oil was added to the crankcase of the small block engine. A similar modification is made in the big-block Chevy engines built by Adams; however, he takes a different approach with the Pontiac 400 series engines. "We have cast a special Pontiac pan with special baffling to keep the engine from cavitating and internally damaging the engine due to lack of oil."

Overall, the Adams lineup of performance handling equipment is one of the best tested, well thought out systems on the market. It can turn your boulevard cruiser into a top notch road racer.

Adams illustration text -

A major difference between Herb Adams' and Dick Guldstrand's street-type suspension kits is in rear leaf spring mounts and control arm mounts. Adams prefers to use the stock rubber leaf spring mount (right) instead of the urethane mounts (senter) used by Guldstrand. Herb feels the urethane is too harsh for the street. For racing applications, Adams sells a special steel bushing (left) which contains a bearing surronded by a sleeving so it will twist as the spring moes up and down.

The front sway bar utilizes a pair of heim joints to improve the efficiency of the bar by eliminating flex. Adams uses a 1 5/16 inch bar as opposed to the stock 1 1/8 inch bar found on late model Chevy Camaros.

To aid in brake cooling, Adams drills five 1 1/2 inch holes through the brake drum and two other holes in the baking plate to allow air to flow through the drum and cool the linings. Note the adjustable Koni shock absorbers.

Adams front strut mounts between the firewall and the upper control arms to control flex of the front suspension.

Part of the reason for the excellent handling characteristics of the Admas Cheverra was the excellent weight distribution, 53 percent on the front wheels compared to 47 percent on the rear. The front air dam was contructed of fiberglass and skirted by flexible rubber, replacing the 100 pound impact bumper system.

The rear sway bar measures a full 1 inch in diameter, replacing the stock 5/8 inch bar. Polyurethane mounts are used to attach the bar to the spring, while the stock rubber mounts are used in the frame connection. These front leaf spring mounts move the front eye of the spring up a full 3/4 inch to lower the rear end of the car and induce anti-squat tendencies.